Steel Pipng ASTM A53/A106 Seamless Pipe Seamless Steel Pipe

Description

ASTM A53 carbon steel pipe covers seamless, welded, black, and hot-dipped galvanized pipe.

| Standard | BS 1387, BS EN 10297, BS 4568, BS EN10217, JIS G3457 |

| Grade | 10#-45#, Cr-Mo alloy, 15NiCuMoNb5, 10Cr9Mo1VNb, A53-A369 |

| Out diameter | 21.3 - 610 mm |

| Wall thickness | 2 - 50 mm |

| Section Shape | Round |

| Application | Fluid Pipe |

| Surface Treatment | varnished,cap,marking |

| Certification | API |

| Carbon Steel Pipe | ASTM A53/106/API 5L B |

| ST37/ST44 Precision Seamless Steel Pipe | DIN 2448/2391/1629/17100 |

| DIN 2391/2448/1629,ST37/ST52 steel pipe | ST37/ST52 |

| Hot Rolled Seamless Steel Pipe | ASTM A 53/106/API 5L B |

| Cold Drawn Seamless Steel Boiler Tube | ASTM A106/DIN 17175/2448 |

| Carbon Seamless Steel Pipe | ASTM A53/106/API 5L B |

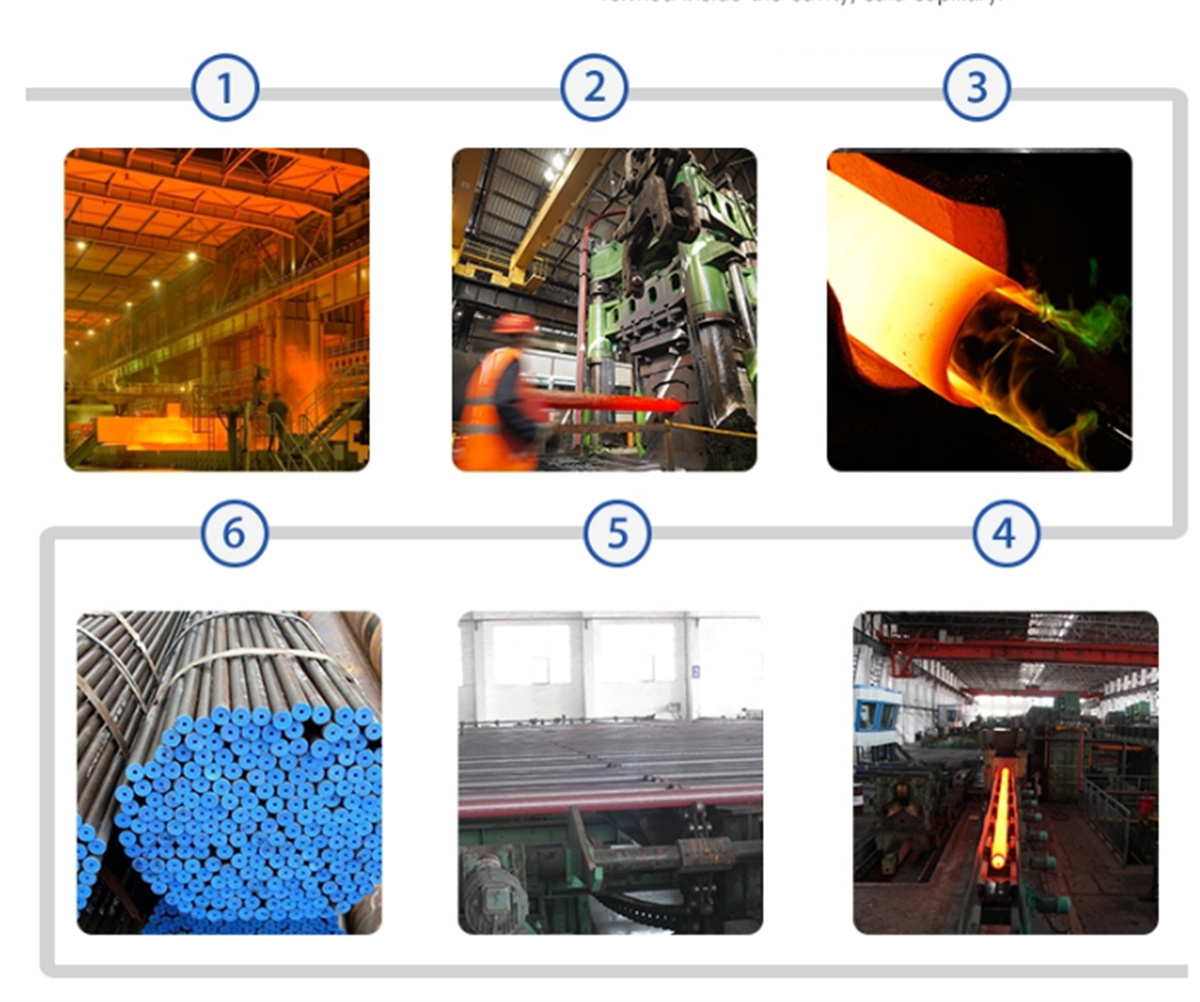

Production Process

Specification

ASTM A53 carbon steel pipe covers seamless, welded, black, and hot-dipped galvanized pipe.

ASTM A53 GRADE A&B

This specification covers seamless and welded black and hot-dipped galvanized steel pipe in nominal size 1/8” in. To 20 in. Inclusive (3.18mm-660.4mm) with nominal (average) wall thickness .

ASTM A106 GRADES A, B & C

This specification covers seamless carbon steel pipe for high temperature service in nominal size 1/8 in. To 26 in. Inclusive (3.18mm-660.4mm)with nominal (average) wall thickness .

Grade A Carbon 0.25% max. Manganese 0.27 to 0.93%

Grade B Carbon 0.30% max. Manganese 0.29 to 1.06%

Grade C Carbon 0.35% max. Manganese 0.29 to 1.06%

All grades have same values for Sulphur 0.058% max. Phosphorus 0.048% max. Silicon 0.20% min.

Standard

Chemical Composition (%):

| Standard | Grade | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTM A53M | A | =0.25 | - | =0.95 | =0.05 | =0.045 | =0.40 | =0.40 | =0.40 | =0.15 | =0.08 |

| B | =0.30 | - | =1.2 | =0.05 | =0.045 | =0.40 | =0.40 | =0.40 | =0.15 | =0.08 |

Mechanical Properties:

| Standard | Grade | Tensile strength (Mpa) | Yield strength (Mpa) | Elongation (%) | |||||

| ASTM A53M | A | =330 | =205 | See table 3 of ASTM A53 | |||||

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Cu |

Mo |

V |

|

ASTMA106M |

A |

=0.25 |

=0.10 |

0.27-0.93 |

=0.035 |

=0.035 |

=0.40 |

=0.40 |

=0.40 |

=0.15 |

=0.08 |

|

B |

=0.30 |

=0.10 |

0.29-1.06 |

=0.035 |

=0.035 |

=0.40 |

=0.40 |

=0.40 |

=0.15 |

=0.08 |

|

|

C |

=0.35 |

=0.10 |

0.29-1.06 |

=0.035 |

=0.035 |

=0.40 |

=0.40 |

=0.40 |

=0.15 |

=0.08 |

Mechanical Properties:

|

Standard |

Grade |

Tensile strength (Mpa) |

Yield strength (Mpa) |

Elongation (%) |

|||

|

ASTM A106M |

A |

=330 |

=205 |

See table 4 of ASTM A106 |

|||

|

B |

=415 |

=240 |

|||||

|

C |

=485 |

=275 |

Painting&Coating

varnished,cap,marking

Packing&Loading

FAQ

Q: How long time your company has been in business?

A: We are manufacturer of construction materials for 20 years in steel industry.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL service. (Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: Do you have mill certificate and material component analysis report?

A:Yes we have professional quality analysis department. We supply quality report for each batch goods.