DIN2391 ST52 BKS COLD DRAWN SEAMLESS STEEL PIPE HYDRAULIC CYLINDER HONED TUBE

Product Description

Key attributes

Section Shape:Round

Surface Treatment:Cold Rolled

Tolerance:±1%

Oiled or Non-oiled:Slightly Oiled

Invoicing:by actual weight

Alloy Or Not:Is Alloy

Standard:ASTM

Grade:ST52

Delivery Time:22-30 days

Brand Name:WF

Application:Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe, Other

Special Pipe:API Pipe, Other, EMT Pipe, Thick Wall Pipe

Thickness:custom

Length:12M, 6m, 6.4M

Certificate:ISO9001

Processing Service:Welding, Punching, Cutting, Bending, Decoiling

Name:Hydraulic Honed Tube

Pipe Type:Cold Drawn Seamless Steel

Inside Processing :Honed/Skived/ Burnished Tubes

Material Grade:SAE1020,1045, ST52

Heat Treatment:Stress Relieved (BK+S)

other grade:ST52, ST52.3, E355

Internal Diameter Accuracy:H7, H8, H9

Internal Surface Roughness:Ra0.2~0.8um

Usage:Hydraulic Cylinder Barrel

Package:Standard Package

|

Honed Tube for Hydraulic Cylinder |

||

| Standard | DIN2391, EN10305, JIS G3445, ASTM A519, GB/T 8713... | |

| Material | ST45, ST52, E355, E355SR, STKM13C, SAE1026, 20#, Q235B, CK45... | |

| Heat treatment | BK+S | |

| Specification | Outer diameter(mm) | Inner diameter(mm) |

| 50-300mm | 30-250 | |

| I.D Tolerance | H8-H9 | |

| Length | 3-9m (Customers usually choose the 4~5.8m) | |

| Straightness | 0.5mm/1000mm | |

| ID roughness | RA 0.4micron(max) | |

| Technology | Honed & SRB(SKIVED AND ROLLER BURNISHED ) | |

| Scope | Honed tube for hydraulic cylinder, swivel crane, injection machine and construction machine application | |

Advantage of Product

1)Professional & skilled, reliable.

2)One-stop total solution

3)ready stock goods with fast delivery

4)Customizable: Non-standard sizes are also available

5)Small quantity is acceptable

6)Cash back: Refund or replacement for any product faulty

Product Parameters

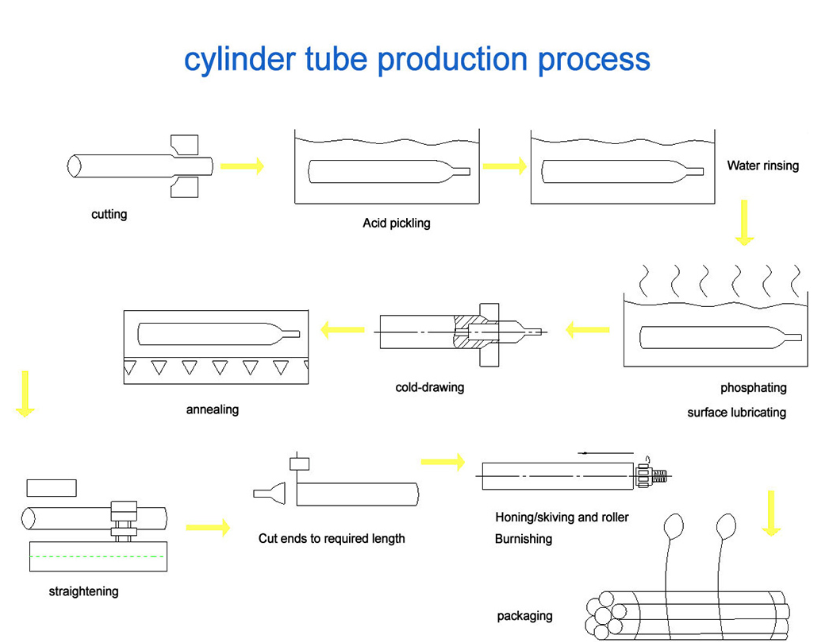

Production Process

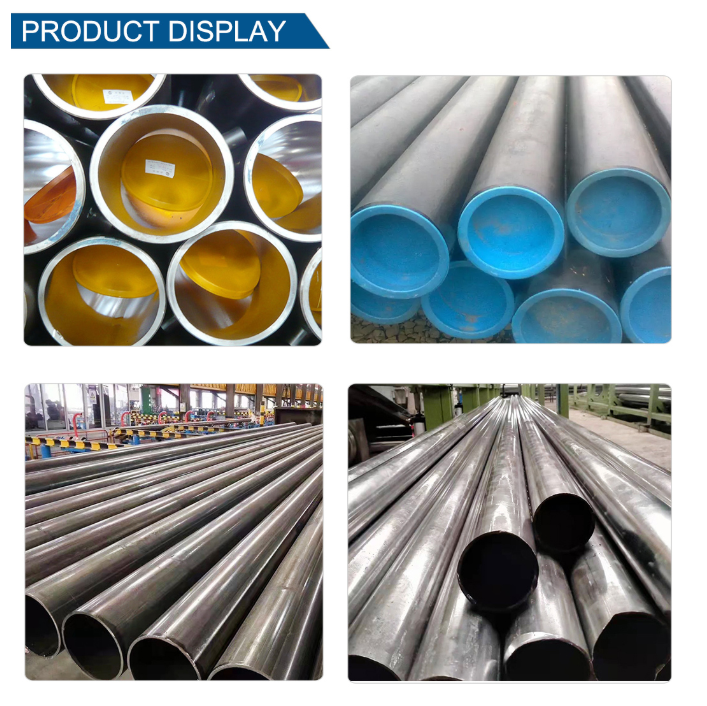

Packaging Details

Anti rust oiled inside surface, plastic caps in both ends

Bundle with steel strip and knitting strip, or wooden case

FAQ

Q: How long could you prepare samples?

A: Normally 1days if we have the sample on hand. lf customized one. about a week around.

Q: How about batch order production?

A: Normally 30days or so for one container.

Q: Do you inspect the finished products?

A: Yes, we will do in spection according to ISO standard and ruled by our QC staff.

Q: What advantage do you have?

A:1.We have professional engineers, customers can expect the best possible advice and support.

2.Related responsible team to answer all your questions and follow-up process for you and do update in time.

3.Strict and standard process control according to Quality Management System.

4.Documents support on products, we have strong technical data sheet to support our products, which could make you easier to know our products.